Understanding Washed Sand and Silica Sand: Which One Fits Your Project?

When you think about sand, you might picture beaches or playgrounds. But in the world of construction and industry, sand is a vital component with very specific characteristics. Not all sand is the same, and choosing the right type is essential for the success and safety of a project. Two of the most common types you’ll encounter are washed sand and silica sand.

While they might look similar, their properties and uses are quite different. Understanding these differences will help you select the best material for your needs, whether you’re mixing concrete, landscaping your yard, or working on an industrial project. Let’s break down what makes each sand unique and where they are best applied.

What is Washed Sand?

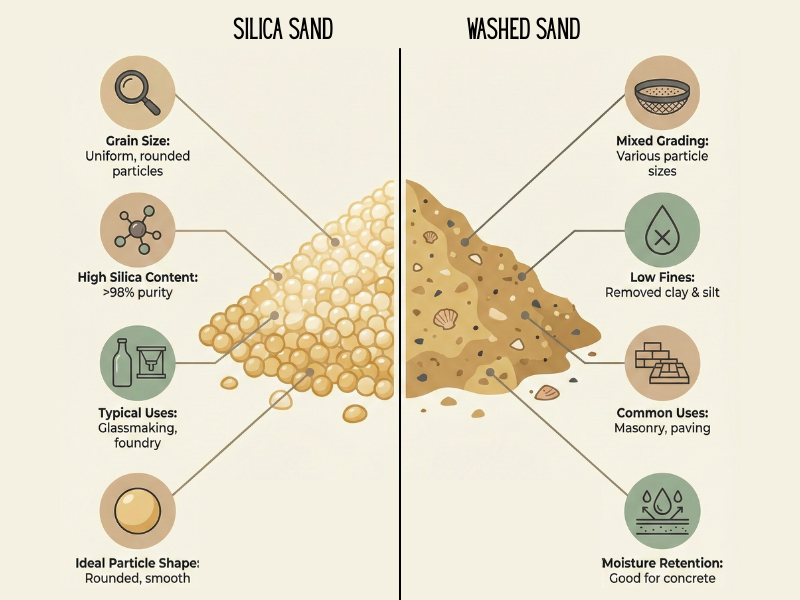

Washed sand is an all-purpose construction material that has been cleaned to remove impurities. You might also hear it called concrete sand or mortar sand because of its frequent use in those applications. The washing process removes unwanted materials like clay, silt, dust, and organic matter, leaving behind a clean and consistent product.

This clean, uniform texture is what makes washed sand so versatile. Without the fine particles of silt and clay, it binds well with cement and water to create strong, durable concrete and mortar.

How is Washed Sand Produced?

The journey for washed sand starts at a natural deposit, such as a riverbed, lake, or quarry. Once excavated, the raw material undergoes a thorough cleaning process.

- Extraction: The sand is gathered from its source.

- Washing: It’s then put through a washing plant where high-pressure water and mechanical agitation work together to scrub the sand particles clean. This process separates the desirable sand grains from finer, unwanted materials like clay and silt.

- Screening: After washing, the sand is screened to ensure a consistent particle size, removing any oversized rocks or debris.

The result of this process is a clean, reliable sand that meets specific standards for construction use. Its clean appearance and predictable performance make it a favorite for many builders.

Common Uses for Washed Sand:

Thanks to its versatility, washed sand is a go-to material for a wide range of projects.

- Concrete and Mortar: This is its primary application. The clean particles create a stronger bond with cement, resulting in durable concrete for foundations, sidewalks, and more. It also provides a smooth consistency for mortar used in bricklaying.

- Landscaping: Washed sand is great for creating a level base for patios and pathways. It’s also used as a top dressing for lawns to improve drainage or mixed into garden soil to prevent compaction.

- Pipe Bedding: It provides a stable and protective bed for underground utility pipes, preventing damage from rocks or shifting soil.

- Play Areas: A finer-grade washed sand is often used in sandboxes and playgrounds because it is clean and soft to the touch.

What is Silica Sand?

Silica sand is a more specialized material defined by its chemical composition rather than just its cleanliness. It is composed almost entirely of silicon dioxide (SiO₂), which comes from quartz crystals. This high silica content gives the sand unique properties, including high strength, hardness, and resistance to heat and chemical reactions.

Because of these distinct characteristics, silica sand is not just a construction material but also a critical component in many industrial processes. It is sometimes referred to as industrial sand or quartz sand.

How is Silica Sand Produced?

Silica sand can be sourced naturally or manufactured, but either way, the goal is to achieve a very high purity of silica.

- Natural Silica Sand: This sand is formed over millions of years from the erosion of quartz-rich rocks like sandstone. Over time, wind and water break down the rock, leaving behind durable quartz grains. These deposits are mined from open pits.

- Manufactured Silica Sand: To achieve even higher purity or specific grain shapes, silica sand can be produced by crushing quartz-rich rock.

After extraction, the sand goes through extensive processing. This includes washing and screening, similar to washed sand, but often involves more advanced steps like drying and sorting by size and shape to meet the strict requirements of industrial applications.

Common Uses for Silica Sand:

The unique properties of silica sand make it indispensable for many specialized applications.

- Glass Manufacturing: This is one of the largest uses for silica sand. Its high purity and silica content are essential for producing all types of glass, from windows to bottles.

- Metal Casting and Foundries: Silica sand is used to create molds and cores for casting molten metal. Its high melting point (over 3,000°F or 1,650°C) allows it to hold its shape when exposed to extreme heat.

- Water Filtration: The uniform grain size of silica sand makes it an excellent filter medium for removing contaminants from drinking water and wastewater.

- Abrasives: Due to its hardness, silica sand is used for sandblasting to clean surfaces, as well as in sandpaper and grinding media.

- Sports Fields: You’ll find silica sand in golf course bunkers and as a component in the turf for athletic fields, where it provides excellent drainage and a consistent playing surface.

| Feature | Silica Sand | Washed Sand |

|---|---|---|

Primary Component |

High Purity Silicon Dioxide (SiO2) |

Mixed minerals (Quartz + Feldspar, etc.) |

Purity (SiO2) |

> 98% - 99.5% |

Typically 80% - 90% |

Particle Shape |

Rounded to Sub-angular (Uniform) |

Angular to Sub-angular (Irregular) |

Grain Size Standard |

AFS Number (e.g., AFS 30, 50, 60) |

ASTM C33 (Concrete) / C144 (Masonry) |

Silt/Clay Content |

Near Zero (Dust-free) |

< 3-5% (Washed to remove mud) |

Specific Gravity |

2.65 (Consistent) |

2.50 – 2.70 (Variable) |

Bulk Density |

~1,500 kg/m³ (95 lb/ft³) - 1,800 kg/m³ (112 lb/ft³) |

~1,430 kg/m³ (90 lb/ft³) - 1700 kg/m³ (106 lb/ft³) |

Hardness (Mohs) |

7 |

7 (for quartz content) |

Choosing the Right Sand for Your Project:

So, how do you decide which sand to use? The choice comes down to the demands of your project.

- For general building and landscaping, washed sand is almost always the right choice. It provides the necessary strength and consistency for concrete, mortar, and paver bases at an affordable cost.

- For industrial or specialty applications, silica sand is necessary. If your project requires high-temperature resistance, chemical inertness, or extreme hardness, only silica sand will do. Using washed sand in its place could lead to project failure.

By understanding the unique properties of washed sand and silica sand, you can make an informed decision and ensure you have the right material for the job. While one provides versatile, clean fill for construction, the other offers the high-purity performance needed for demanding industrial processes. Choosing correctly ensures the quality, safety, and longevity of your work.

If you have any questions or concerns about our services, our team of friendly and knowledgeable customer service representatives are available to assist you.